Introduction: Revolutionizing Spectroscopy in Hazardous Locations

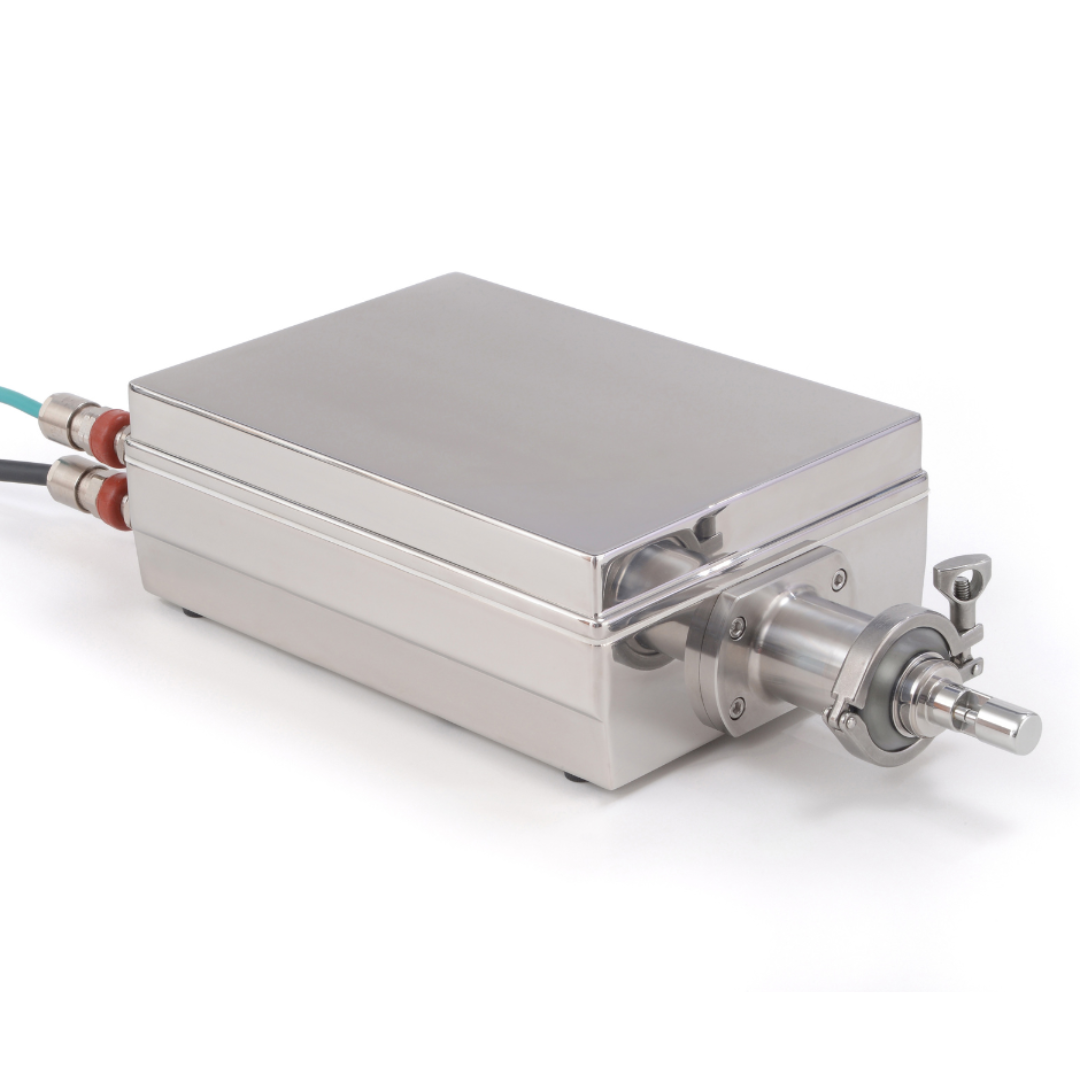

In industries where safety is paramount, the Phoenix EX stands out as a groundbreaking solution. With certifications for gas and dust hazardous locations, it eliminates the need for purge and pressurization, offering a cost-effective and efficient alternative. Its rugged stainless steel enclosure ensures durability, while its compatibility with a wide range of spectroscopic techniques makes it a versatile choice.

Bringing Spectral Innovation from the Laboratory to the Factory Floor

The Phoenix EX is designed to deliver laboratory-quality spectroscopic analysis directly to the factory floor. Its compact, robust design means no additional analyzer shelter is required, drastically cutting down installation and maintenance costs. The system supports measurements in ultraviolet, visible, near-infrared, and mid-infrared ranges, making it suitable for a variety of products, including powders, liquids, gases, and gels.

Key benefits of real-time measurements:

- Boost process efficiency

- Reduce material waste

- Enable real-time quality control

- Ensure regulatory compliance

- Guarantee product quality

Innovative AI-Enabled Architecture

Powered by Nova Industrial Analytics’ custom electronics, the Phoenix EX integrates seamlessly into modern industrial processes. Its advanced features include:

- Complete instrumentation control and data acquisition

- Internal storage for spectra, methods, and results

- Embedded Industrial Windows OS for streamlined operations

- Communication via multiple protocols for enhanced connectivity

World’s First Interchangeable Process Interface for Hazardous Locations

The Phoenix EX introduces an industry-first feature: interchangeable process interfaces that can be replaced even in hazardous areas. These interfaces support absorption and reflection measurements and optional temperature measurement, enabling unmatched precision for solids, liquids, gases, gels, and pastes.