In a world where industrial processes are becoming increasingly complex and hazardous environments are more prevalent, the need for sophisticated monitoring solutions has never been more critical.

Nova Industrial Analytics stands at the forefront of this challenge, pioneering the development of cutting-edge technologies designed to ensure safety and enhance efficiency in these high-risk areas. In this blog, we delve into the innovative spectral sensors and software solutions developed by Nova Industrial Analytics, demonstrating how they are reshaping safety protocols and operational efficiency across various industries.

A New Era in Monitoring Technology

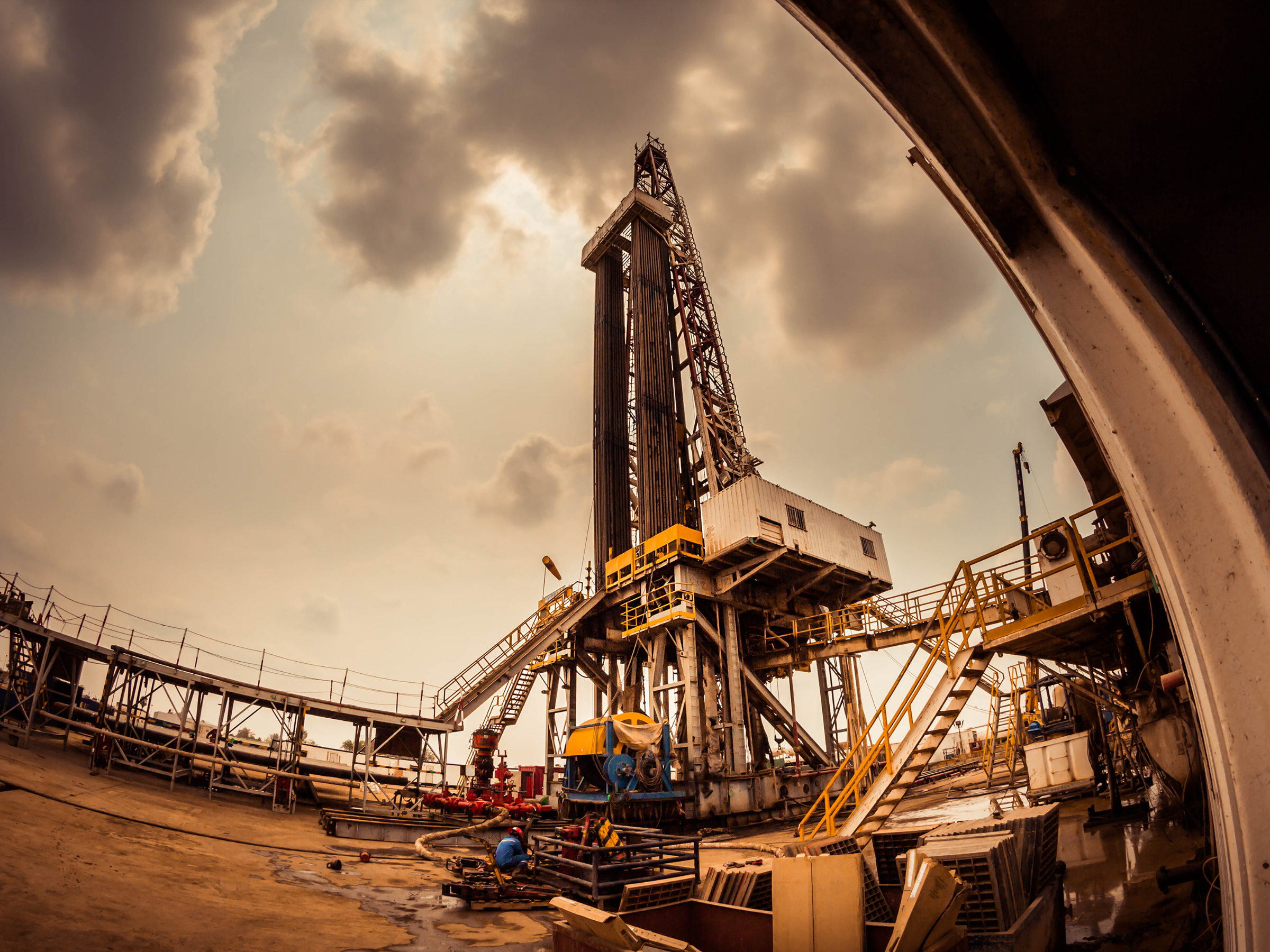

Nova Industrial Analytics has revolutionized the field of hazardous environment monitoring with its state-of-the-art spectral sensors. These sensors represent a significant leap forward in terms of accuracy, reliability, and real-time data processing. In industries such as Oil and Gas, Chemical Manufacturing, and Pharmaceuticals, where the margin for error is minimal, these advancements are not just improvements – they are necessities.

Transforming Safety Protocols

Safety in hazardous environments is paramount. Nova Industrial Analytics’ technologies have been instrumental in transforming traditional safety protocols. By providing real-time monitoring and data analysis, these sensors allow for immediate response to potential hazards, significantly reducing the risk of accidents and ensuring a safer working environment. This real-time capability is crucial in industries like Oil and Gas, where the early detection of leaks or hazardous conditions can prevent disasters.

Enhancing Efficiency in Operations

Efficiency is another critical area where Nova Industrial Analytics has made significant strides. Their spectral sensors and software are designed for seamless integration into existing processes, providing a smooth transition from lab to field operations. This integration is vital for maintaining continuous and efficient operations, especially in sectors like Chemical Manufacturing, where process control is essential for product quality and safety.

Advancements in Real-Time Process Control

One of the most significant advancements in Nova Industrial Analytics’ technology is in the realm of real-time process control. This innovation allows for the continuous monitoring of processes, ensuring that parameters remain within safe and optimal ranges. It is a game-changer for industries like Pharmaceuticals, where maintaining strict control over the manufacturing process is crucial for ensuring the efficacy and safety of drugs.

Seamless Lab-Process Integration

Another area where Nova Industrial Analytics excels is in the integration of laboratory and process environments. This integration is crucial for ensuring that the data and insights gained in the lab can be effectively applied in the field. It ensures consistency, accuracy, and reliability in monitoring, which is essential for industries that rely heavily on precise measurements and strict quality controls.

Nova Industrial Analytics’ Role in Shaping the Future

The role of Nova Industrial Analytics in shaping the future of hazardous environment monitoring cannot be overstated. Their continuous innovation and commitment to developing advanced technologies are setting new standards in the industry. By constantly pushing the boundaries of what is possible, Nova Industrial Analytics is not only providing solutions for today’s challenges but is also paving the way for safer and more efficient industrial processes in the future.

Conclusion

The advancements in hazardous environment monitoring technology by Nova Industrial Analytics mark a significant step forward in ensuring safety and efficiency in critical industries. As these technologies continue to evolve, we can expect to see even greater improvements in how we monitor and manage these challenging environments. Nova Industrial Analytics is not just keeping pace with these changes; they are leading the charge, ensuring a safer and more efficient future for industries worldwide.